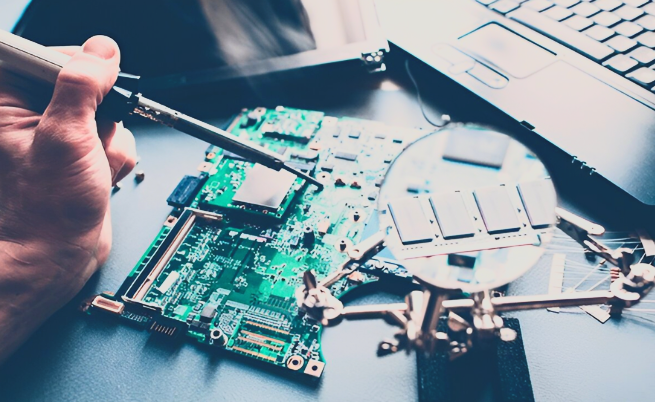

SMT PCB assembly (Surface Mount Technology Printed Circuit Board assembly) is one of the most advanced and widely used techniques in electronics manufacturing today. Unlike traditional through-hole assembly methods, where components are inserted into drilled holes, SMT involves mounting electronic components directly onto the surface of the PCB. This process allows for greater design flexibility, higher component density, and improved electrical performance, making it the foundation of modern electronics production.

Whether it’s for smartphones, medical instruments, automotive systems, or industrial machinery, SMT PCB assembly enables manufacturers to create smaller, lighter, and more reliable devices that meet the growing demands of the technology-driven world.

The SMT PCB Assembly Process

The SMT PCB assembly process is a precise, multi-step operation that requires advanced machinery and skilled engineering. The main steps include:

- Solder Paste Application: The process begins with applying solder paste onto the pads of the PCB using a stencil printer. This paste acts as the bonding material between the board and surface-mounted components.

- Pick and Place: Automated pick-and-place machines accurately position tiny surface-mount components on the board according to the design file. These machines can place thousands of components per hour with micrometre-level precision.

- Reflow Soldering: The assembled board is then passed through a reflow oven. The solder paste melts and solidifies, permanently attaching the components to the PCB surface.

- Inspection and Quality Control: Automated optical inspection (AOI) systems and X-ray testing ensure each component is correctly placed and properly soldered, maintaining the high reliability required for critical applications.

This process allows for high-speed production and consistent quality across large volumes, making SMT assembly the industry standard.

Benefits of SMT PCB Assembly

The shift to SMT PCB assembly has revolutionised the electronics industry due to its numerous advantages over older methods. Some of the key benefits include:

- Compact and Lightweight Designs: Components can be placed on both sides of the PCB, allowing for smaller and thinner devices.

- High Production Efficiency: Automated processes reduce human error, speed up production, and increase output rates.

- Improved Electrical Performance: Shorter electrical paths between components reduce resistance and inductance, enhancing signal integrity and circuit reliability.

- Cost Efficiency for Mass Production: Despite requiring advanced machinery, SMT offers lower per-unit costs for large-scale production due to its automation and speed.

- Strong Mechanical Performance: Reflow soldering creates strong joints that can withstand vibration and mechanical stress, essential in automotive and aerospace electronics.

These advantages make SMT assembly the go-to method for nearly all modern electronic products.

SMT Components and Design Considerations

The components used in SMT PCB assembly are smaller and more diverse than those used in through-hole designs. Common surface-mount components include resistors, capacitors, diodes, ICs, and transistors.

When designing an SMT PCB, engineers must pay close attention to pad size, spacing, and thermal relief to ensure proper soldering and electrical performance. Moreover, component orientation and polarity must be precisely defined in the design files to avoid placement errors during automated assembly.

Thermal management is another key consideration, as densely packed components can generate heat. Using thermal vias and proper copper trace design ensures efficient heat dissipation.

Quality Assurance in SMT PCB Assembly

Reliability is crucial in SMT PCB assembly, especially for applications in medical, aerospace, and industrial sectors. To maintain quality, manufacturers employ strict inspection and testing protocols throughout production.

- AOI (Automated Optical Inspection): Checks for missing, misaligned, or incorrectly soldered components.

- X-ray Inspection: Detects hidden solder defects, especially in Ball Grid Array (BGA) packages.

- In-Circuit Testing (ICT): Verifies electrical connectivity and functionality of individual components.

- Functional Testing: Ensures the final assembled PCB performs as intended under real-world conditions.

By combining automation with thorough quality control, SMT PCB assembly guarantees both precision and durability.

Applications of SMT PCB Assembly

SMT PCB assembly is used across a wide range of industries where performance, reliability, and compact design are essential. Key application areas include:

- Consumer Electronics: Smartphones, tablets, smartwatches, and home appliances.

- Automotive Electronics: Engine control units, sensors, and infotainment systems.

- Medical Devices: Monitoring equipment, diagnostic tools, and wearable health technology.

- Telecommunications: Network equipment, routers, and communication modules.

- Industrial Automation: Controllers, power modules, and robotics.

The adaptability of SMT technology makes it suitable for both high-volume production and complex, multi-layer PCB designs.

SMT vs. Through-Hole Assembly

While through-hole assembly is still used for certain high-strength or high-voltage components, SMT PCB assembly offers significant advantages in speed, miniaturisation, and cost efficiency. Through-hole assembly requires drilling holes into the PCB, limiting the number of components that can be mounted and increasing production time.

In contrast, SMT eliminates the need for holes, allowing components to be placed on both sides of the board. This innovation has enabled the rise of compact devices like smartphones and IoT modules, where every millimetre of space matters.

Conclusion

In today’s fast-paced electronics industry, SMT PCB assembly stands as the cornerstone of precision manufacturing. It combines speed, reliability, and high performance, enabling the creation of advanced electronic devices that power everything from consumer gadgets to industrial machinery.

For businesses looking to develop high-quality electronic products, partnering with experts that offer professional PCB assembly services is essential. A reliable partner can provide complete solutions—from component sourcing and assembly to testing and quality assurance—ensuring every PCB meets international standards and performs flawlessly in real-world applications.