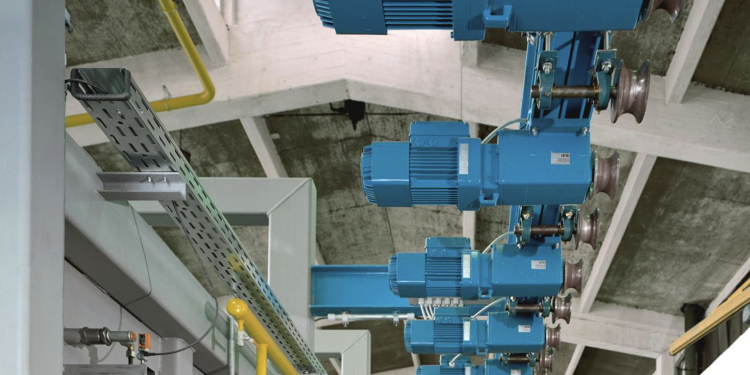

Geared motors are used in various industrial applications to control power and motion.

Geared motors are a type of electric motor that uses multiple gears to produce motion at different speeds and in different directions. The gears are usually connected to a shaft and can be adjusted to produce different torque and speed levels.

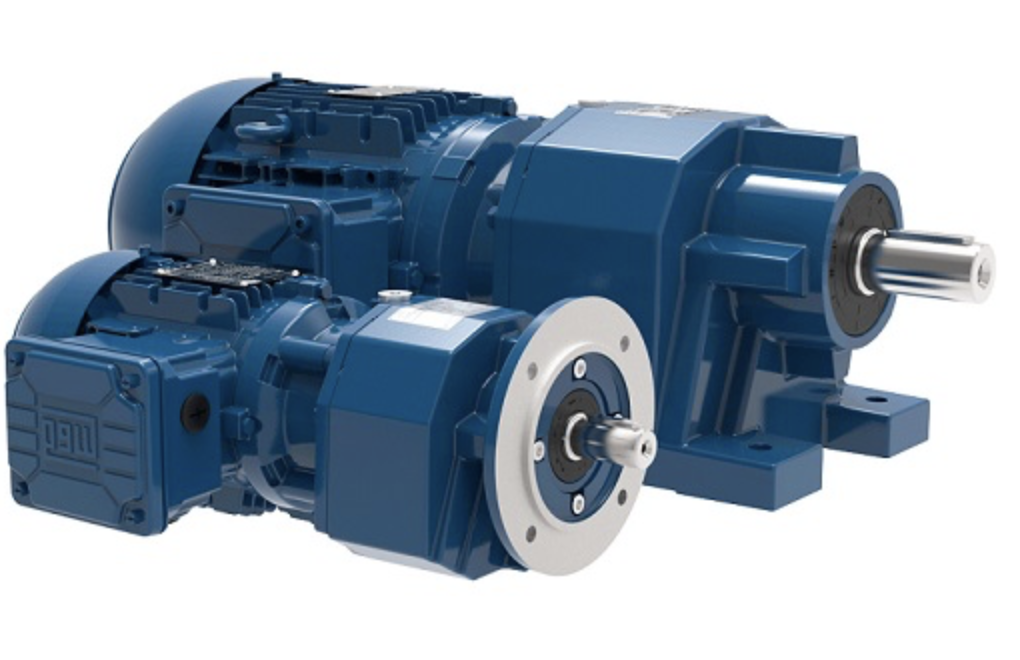

Geared motors are ideal for applications requiring precise speed and torque control and provide reliable performances in harsh environments. Geared motors are typically composed of a motor, gearbox, and a power transmission system. The motor generates the power to drive the gears, while the gearbox and power transmission system convert the motor’s rotational force into the desired speed and torque.

Geared motors work by transferring the rotational force of the motor to the output shaft. The motor is connected to a gearbox that contains several gears. The gears in the gearbox work together to reduce the speed of the motor while increasing its torque. The gearbox’s output shaft is attached to the desired application, such as a conveyor belt or robotic arm.

The number and size of the gears in the gearbox determine the output torque and speed of the motor. For example, if a motor is connected to a gearbox with a 5:1 gear ratio, the output shaft will turn five times slower than the input shaft but with five times the torque. This gear ratio can be adjusted to meet the needs of the application.

Geared motors are available in a variety of sizes and configurations. They are typically rated in terms of power output, speed, and torque. The most common type is the three-phase AC motor, which is used in many industrial applications. Other types of geared motors include DC motors and servo motors.

An AC geared motor is usually a high-power gear motor ranging from 1hp to 5hp and higher. While a DC gear motor is usually a small power gear motor, no more than 0.5 hp. AC-geared motors generally require less maintenance and are easier to install, especially in potentially wet, hard-to-reach, or otherwise hazardous environments.

DC-geared motors offer better control speed and torque, making them better suited for applications where precise control is necessary. A DC gear motor’s efficiency depends on the load and speed, making it difficult to achieve consistent performance. Also, the cost of a DC gear motor is usually higher than an AC motor.

Servo-geared motors are composed of a motor, a gearbox, and an encoder. The motor provides the rotational force, while the gearbox converts the rotational force into linear or angular motion. The encoder measures the angular position of the motor and sends this information to the control system. This allows the control system to control the motion of the motor precisely. Servo-geared motors are commonly used in robotic and automated systems to control movement and position precisely.

In conclusion, a geared motor is an electric motor that incorporates gears to increase the torque of a motor. The gears in a geared motor decrease the motor’s speed while increasing its torque.